Optimized Technical Specification of UHP Waterjet Nozzle Solutions

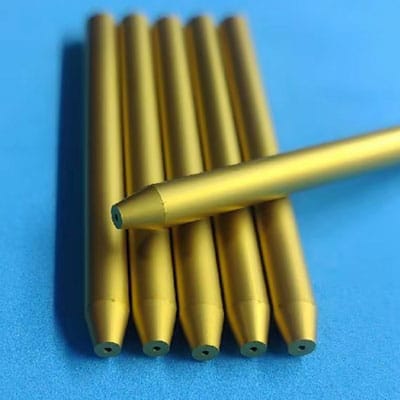

Our ultra-high pressure (UHP) waterjet nozzle (Mixing Tubes) portfolio comprises multiple series engineered to deliver optimal balance of cost-effectiveness and operational efficiency for diverse industrial applications. Specifically engineered for UHP waterjet cutting systems, these nozzles feature micron-level orifice tolerances (±0.002mm) and radial concentricity <0.005mm, ensuring continuous process stability and repeatable cutting accuracy across extended operational cycles.

Manufactured through a vertically integrated production process, our nozzles undergo rigorous quality control from tungsten carbide powder metallurgy through:

- Isostatic pressing for uniform density distribution

- CNC contour grinding with 5-axis precision machining

- Electrical discharge machining (EDM) for final surface refinement

This comprehensive manufacturing protocol ensures consistent compliance with ASME B94.55M standards, achieving: - Vickers hardness ≥2200 HV30

- Surface roughness Ra ≤0.1μm

- Minimum service life of 150-200 operational hours

Through continuous R&D investments in fluid dynamics optimization, we maintain industry-leading nozzle designs that maximize energy transfer efficiency (typically >92%) while minimizing kerf taper angle (<0.5° for 100mm thick materials).

Waterjet Abrasive Tube Dimensions and Brand Comparison

Precision Standards:

- with ISO 2768-m precision tolerance (±0.005mm inner diameter).

- laser-calibrated (EN ISO 9013 certified).

water-jet nozzles Dimensions

| No. | ØD OD | Ød ID | L Length | |||

| [mm] | [inch] | [mm] | [inch] | [mm] | [inch] | |

| 1 | 6.00 | 0.236 | 0.51 | 0.020 | 70.00 | 2.76 |

| 2 | 6.35 | 1/4 | 0.60 | 0.023 | 76.20 | 3 |

| 3 | 6.69 | 0.263 | 0.76 | 0.030 | 88.90 | 3.5 |

| 4 | 6.70 | 0.264 | 0.84 | 0.033 | 101.60 | 4 |

| 5 | 7.00 | 0.276 | 0.89 | 0.035 | 127.00 | 5 |

| 6 | 7.14 | 9/32 | 0.91 | 0.036 | 152.40 | 6 |

| 7 | 7.62 | 0.300 | 1.02 | 0.040 | ||

| 8 | 7.97 | 0.313 | 1.14 | 0.045 | ||

| 9 | 9.00 | 0.354 | 1.20 | 0.047 | ||

| 10 | 9.43 | 0.371 | 1.27 | 0.050 |

Brand Comparison

| OD | ID | Length | Model/Part Number | Compatible Equipment | Adaptable Brands |

| 6.35 | 0.76 | 76.2 | WJNS Standard | FLOW Mach3 Series | CERATIZIT |

| 7.14 | 1.02 | 76.2 | WJNP Reinforced | OMAX 55100 | |

| 9.00 | 1.27 | 89.0 | ROCTEC 500 | Bystronic High-Pressure Systems | KENNAMETAL |

| 8.00 | 0.63 | 76.0 | WJNAO Economy | Portable Cutting Machines | HyproJET |

| 6.35 | 0.25* | 76.2 | 6.35mm Series | Jet Edge X-Stream | Jet Edge |

| 9.00 | 1.02 | 102.0 | Custom Long Tube | 5-Axis Cutting Robots | WJS |

| *Note: The "0.25-inch" inner diameter in Jet Edge models equals 6.35mm, a special U.S. standard specification. |

Water-jet Grades

| Grade | Binder [%] | Density [g/cm°] | Hardness [HV10] | Compressive [Mpa] | strengths [P.S.I.] |

| YC01U | 0.41 | 15.50 | 2650 | 12500 | 332000 |

| YC02U | 0.26 | 15.55 | 2800 | 13000 | 285000 |

Waterjet Nozzle Application Fields

Key Industrial Applications

- Precision Material Cutting

Widely utilized for precision cutting of metals, stone, glass, ceramics, and composite materials in automotive, aerospace, and construction industries. - Industrial Cleaning & Surface Preparation

High-pressure waterjet nozzles effectively remove oil, rust, and contaminants for ship maintenance, industrial equipment refurbishment, and infrastructure cleaning. - Advanced Material Processing

Enables milling, drilling, and shaping of complex geometries, ideal for aerospace components, turbine blade machining, and intricate part fabrication. - Food Processing & Packaging

Delivers hygienic cutting and cleaning solutions for food products, eliminating thermal distortion while meeting EU food safety standards (EC 852/2004 compliance). - Waste Recycling & Management

Processes mixed industrial waste streams for material recovery, particularly effective in separating metals/polymers from electronic scrap. - Environmental Remediation

Deploys eco-friendly contaminant removal for soil decontamination and aquatic system rehabilitation projects across EU environmental regulations. - High-Precision Manufacturing

Supports rapid prototyping, mold fabrication, and micromachining for medical device production and optical component manufacturing. - Medical & Bioengineering

Facilitates sterile processing of surgical instruments and non-contact cutting for implant manufacturing (e.g., titanium alloys), meeting ISO 13485 standards.

Technical Advantages for EU Markets

- ≤0.8° kerf taper for 200mm-thick materials (EN ISO 9013 compliant)

- 95% abrasive utilization efficiency (CE-certified systems)

- Integrated IoT monitoring compatible with Industry 4.0 workflows