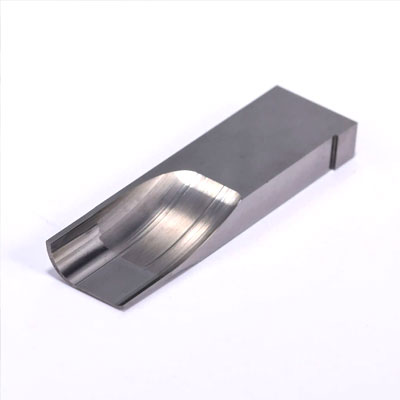

Carburo de tungsteno Es un material popular en la fabricación por su excelente dureza, resistencia al desgaste y resistencia. Sin embargo, su mecanizado puede ser complejo debido a su alta dureza y fragilidad. En este artículo, analizaremos los diversos métodos de mecanizado. carburo de tungsteno, sus consideraciones, ventajas y desventajas.

Métodos de mecanizado de carburo de tungsteno

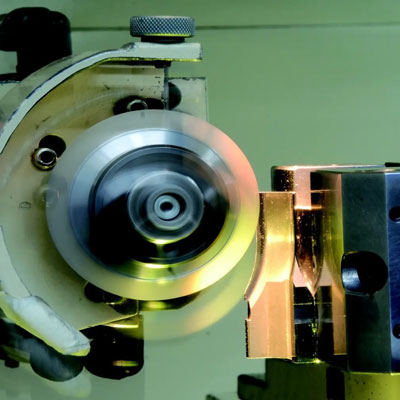

- Rectificado: El rectificado es el método de mecanizado más común. carburo de tungstenoImplica el uso de una muela abrasiva para eliminar material de la pieza de trabajo. La muela está compuesta de partículas abrasivas unidas mediante un aglutinante. Los granos abrasivos de diamante o nitruro de boro cúbico (CBN) se utilizan comúnmente para el rectificado. carburo de tungsteno.

- EDM (mecanizado por descarga eléctrica): la electroerosión es un método no tradicional de mecanizado que utiliza energía eléctrica para eliminar material de la pieza de trabajo. En la electroerosión, una herramienta conductora y una pieza de trabajo se sumergen en un fluido dieléctrico. Luego se utiliza una descarga eléctrica para eliminar material de la pieza de trabajo. La electroerosión se utiliza a menudo para formas y perfiles complejos.

- Corte por láser: El corte por láser utiliza un rayo láser de alta energía para cortar y dar forma. carburo de tungstenoEl rayo láser funde el material y un chorro de gas a alta presión lo expulsa de la pieza. El corte por láser es adecuado para secciones delgadas y formas complejas.

Consideraciones para el mecanizado de carburo de tungsteno

- Selección de herramientas: La elección del material de la herramienta es crucial para el mecanizado. carburo de tungsteno. Las herramientas de diamante o CBN se utilizan comúnmente para rectificar, mientras que carburo de tungsteno o para la electroerosión se utilizan herramientas de cobre-tungsteno.

- Fijación de piezas de trabajo: Debido a la fragilidad de carburo de tungstenoLa fijación adecuada de la pieza de trabajo es esencial para evitar grietas o astillas durante el mecanizado.

- Parámetros de mecanizado: Los parámetros de mecanizado como la velocidad de corte, el avance y la profundidad de corte deben seleccionarse cuidadosamente para evitar un desgaste excesivo de la herramienta o daños a la pieza de trabajo.

Ventajas y desventajas de cada método de mecanizado

- Rectificado: El rectificado es el método de mecanizado más común y rentable. carburo de tungstenoProporciona un acabado de alta calidad y se puede utilizar tanto para desbaste como para acabado. Sin embargo, el desbaste puede requerir mucho tiempo y la vida útil de la herramienta puede ser limitada.

- EDM: La electroerosión es adecuada para mecanizar formas y perfiles complejos en carburo de tungstenoNo produce calor ni tensión mecánica, lo que la hace ideal para piezas frágiles. Sin embargo, la electroerosión puede ser más lenta que otros métodos y producir un acabado superficial más rugoso.

- Corte por láser: El corte por láser es rápido y preciso y puede producir formas intrincadas en carburo de tungstenoNo produce tensión mecánica y el desgaste de la herramienta es mínimo. Sin embargo, el corte por láser puede ser costoso y se limita a secciones delgadas.

Conclusión

Mecanizado carburo de tungsteno Requiere una cuidadosa consideración de la selección de herramientas, la fijación de la pieza y los parámetros de mecanizado. El rectificado es el método de mecanizado más común y rentable. carburo de tungstenoMientras que la electroerosión y el corte por láser son adecuados para formas complejas y secciones delgadas. Cada método tiene sus ventajas y desventajas, y la elección del método dependerá de los requisitos específicos de la aplicación. Con las técnicas y el equipo de mecanizado adecuados, carburo de tungsteno Se puede mecanizar para producir piezas de alta calidad con excelente resistencia al desgaste y resistencia.