Tungsten karbür mükemmel sertliği, aşınma direnci ve dayanıklılığı nedeniyle üretimde kullanılan popüler bir malzemedir. Ancak, yüksek sertliği ve kırılganlığı nedeniyle bu malzemeyi işlemek zor olabilir. Bu makalede, çeşitli işleme yöntemlerini tartışacağız tungsten karbür, bunların değerlendirmeleri, avantajları ve dezavantajları.

Tungsten Karbür İşleme Yöntemleri

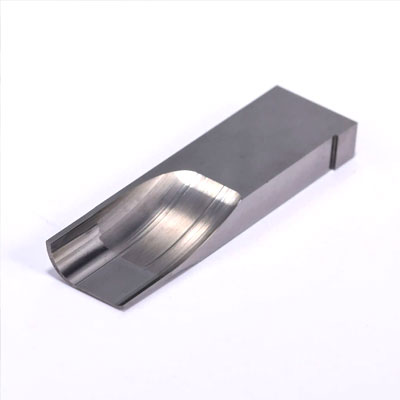

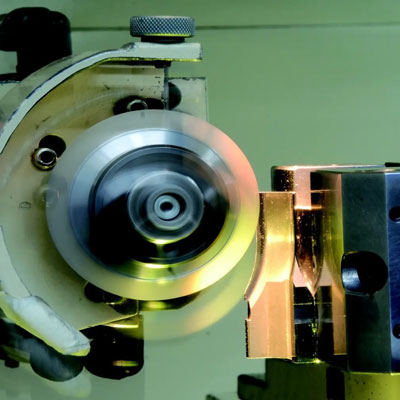

- Taşlama: Taşlama, işlemenin en yaygın yöntemidir tungsten karbür. İş parçasından malzemeyi çıkarmak için bir taşlama çarkının kullanılmasını içerir. Taşlama çarkı, bir bağlayıcı malzeme ile birbirine bağlanmış aşındırıcı parçacıklardan yapılır. Elmas veya kübik bor nitrür (CBN) aşındırıcı tanecikler genellikle taşlama için kullanılır tungsten karbür.

- EDM (Elektrikli Deşarj İşleme): EDM, malzemeyi iş parçasından çıkarmak için elektrik enerjisi kullanan, geleneksel olmayan bir işleme yöntemidir. EDM'de iletken bir alet ve iş parçası bir dielektrik sıvıya batırılır. Daha sonra malzemeyi iş parçasından çıkarmak için bir elektrik deşarjı kullanılır. EDM genellikle karmaşık şekiller ve profiller için kullanılır.

- Lazer Kesim: Lazer kesim, kesmek ve şekillendirmek için yüksek enerjili bir lazer ışını kullanır tungsten karbürLazer ışını malzemeyi eritir ve yüksek basınçlı bir gaz jeti erimiş malzemeyi iş parçasından uzağa üfler. Lazer kesim ince kesitler ve karmaşık şekiller için uygundur.

Tungsten Karbürün İşlenmesinde Dikkat Edilmesi Gerekenler

- Takım Seçimi: Takım malzemesinin seçimi, işleme için çok önemlidir tungsten karbür. Taşlama için genellikle elmas veya CBN takımları kullanılırken, tungsten karbür veya bakır-tungsten takımlar EDM için kullanılır.

- İş Parçası Fikstürleme: İş parçasının kırılganlığı nedeniyle tungsten karbürİşleme sırasında çatlama veya kırılmayı önlemek için iş parçasının uygun şekilde sabitlenmesi önemlidir.

- İşleme Parametreleri: Aşırı takım aşınmasını veya iş parçasına zarar gelmesini önlemek için kesme hızı, ilerleme hızı ve kesme derinliği gibi işleme parametreleri dikkatlice seçilmelidir.

Her İşleme Yönteminin Avantajları ve Dezavantajları

- Taşlama: Taşlama, işlemenin en yaygın ve uygun maliyetli yöntemidir tungsten karbür. Yüksek kaliteli bir yüzey sağlar ve hem kaba hem de son taşlama için kullanılabilir. Ancak taşlama zaman alıcı olabilir ve takım ömrü sınırlı olabilir.

- EDM: EDM, karmaşık şekillerin ve profillerin işlenmesi için uygundur. tungsten karbürIsı veya mekanik stres üretmez, bu da onu kırılgan parçalar için ideal hale getirir. Ancak, EDM diğer yöntemlerden daha yavaş olabilir ve daha pürüzlü bir yüzey kalitesi üretebilir.

- Lazer Kesim: Lazer kesim hızlı ve hassastır ve karmaşık şekiller üretebilir. tungsten karbür. Mekanik stres üretmez ve minimum takım aşınması vardır. Ancak, lazer kesim pahalı olabilir ve ince kesitlerle sınırlıdır.

Çözüm

İşleme tungsten karbür takım seçimi, iş parçası fikstürü ve işleme parametrelerinin dikkatli bir şekilde değerlendirilmesini gerektirir. Taşlama, en yaygın ve maliyet açısından en etkili işleme yöntemidir tungsten karbür, EDM ve lazer kesim ise karmaşık şekiller ve ince kesitler için uygundur. Her yöntemin kendine göre avantajları ve dezavantajları vardır ve yöntem seçimi uygulamanın özel gereksinimlerine bağlı olacaktır. Uygun işleme teknikleri ve ekipmanlarıyla, tungsten karbür Mükemmel aşınma direnci ve mukavemete sahip yüksek kaliteli parçalar üretmek için işlenebilir.