کاربید تنگستن یک ماده محبوب است که به دلیل سختی، مقاومت در برابر سایش و استحکام عالی در تولید مورد استفاده قرار میگیرد. با این حال، ماشینکاری این ماده به دلیل سختی و شکنندگی بالا میتواند چالش برانگیز باشد. در این مقاله، روشهای مختلف ماشینکاری را مورد بحث قرار خواهیم داد. کاربید تنگستن، ملاحظات، مزایا و معایب آنها.

روشهای ماشینکاری کاربید تنگستن

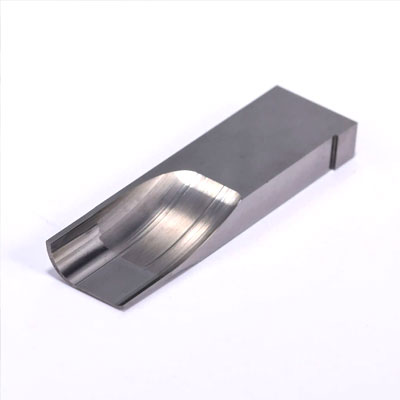

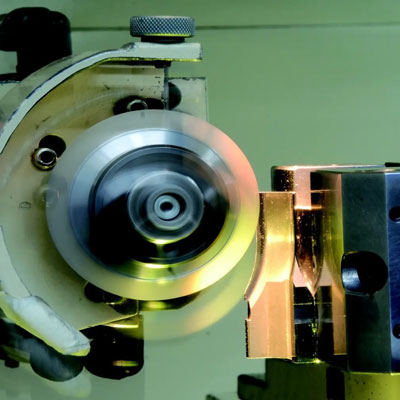

- سنگزنی: سنگزنی رایجترین روش ماشینکاری است. کاربید تنگستناین شامل استفاده از یک چرخ سنگزنی برای برداشتن مواد از قطعه کار است. چرخ سنگزنی از ذرات سایندهای ساخته شده است که با یک ماده چسبنده به هم متصل شدهاند. دانههای ساینده الماس یا نیترید بور مکعبی (CBN) معمولاً برای سنگزنی استفاده میشوند. کاربید تنگستن.

- EDM (Electrical Discharge Machining): EDM یک روش غیر سنتی ماشینکاری است که از انرژی الکتریکی برای حذف مواد از قطعه کار استفاده می کند. در EDM، یک ابزار رسانا و یک قطعه کار در یک سیال دی الکتریک غوطه ور می شوند. سپس یک تخلیه الکتریکی برای حذف مواد از قطعه کار استفاده می شود. EDM اغلب برای اشکال و پروفیل های پیچیده استفاده می شود.

- برش لیزری: برش لیزری از پرتو لیزر با انرژی بالا برای برش و شکلدهی استفاده میکند. کاربید تنگستنپرتو لیزر ماده را ذوب میکند و یک جت گاز پرفشار، ماده مذاب را از قطعه کار دور میکند. برش لیزری برای مقاطع نازک و اشکال پیچیده مناسب است.

ملاحظات برای ماشینکاری کاربید تنگستن

- انتخاب ابزار: انتخاب جنس ابزار برای ماشینکاری بسیار مهم است. کاربید تنگستنابزارهای الماسه یا CBN معمولاً برای سنگزنی استفاده میشوند، در حالی که کاربید تنگستن یا از ابزارهای مس-تنگستن برای EDM استفاده میشود.

- فیکسچرینگ قطعه کار: به دلیل شکنندگی کاربید تنگستن، فیکسچرینگ مناسب قطعه کار برای جلوگیری از ترک خوردن یا لب پریدگی در حین ماشینکاری ضروری است.

- پارامترهای ماشینکاری: پارامترهای ماشینکاری مانند سرعت برش، سرعت تغذیه و عمق برش باید با دقت انتخاب شوند تا از سایش بیش از حد ابزار یا آسیب به قطعه کار جلوگیری شود.

مزایا و معایب هر روش ماشینکاری

- سنگزنی: سنگزنی رایجترین و مقرونبهصرفهترین روش ماشینکاری است. کاربید تنگستناین دستگاه پرداخت نهایی با کیفیتی ارائه میدهد و میتواند هم برای سنگزنی خشن و هم برای سنگزنی نهایی مورد استفاده قرار گیرد. با این حال، سنگزنی میتواند زمانبر باشد و عمر ابزار میتواند محدود باشد.

- EDM: EDM برای ماشینکاری اشکال و پروفیلهای پیچیده مناسب است. کاربید تنگستناین روش گرما یا تنش مکانیکی ایجاد نمیکند و آن را برای قطعات شکننده ایدهآل میکند. با این حال، EDM میتواند کندتر از سایر روشها باشد و ممکن است سطح نهایی ناهموارتری ایجاد کند.

- برش لیزری: برش لیزری سریع و دقیق است و میتواند اشکال پیچیدهای را ایجاد کند. کاربید تنگستن. این روش تنش مکانیکی ایجاد نمیکند و حداقل سایش ابزار را دارد. با این حال، برش لیزری میتواند گران باشد و به مقاطع نازک محدود میشود.

نتیجه

ماشینکاری کاربید تنگستن نیاز به بررسی دقیق انتخاب ابزار، تثبیت قطعه کار و پارامترهای ماشینکاری دارد. سنگ زنی رایج ترین و مقرون به صرفه ترین روش ماشینکاری است کاربید تنگستندر حالی که برش EDM و لیزر برای اشکال پیچیده و مقاطع نازک مناسب هستند. هر روش مزایا و معایب خود را دارد و انتخاب روش به الزامات خاص کاربرد بستگی دارد. با تکنیکها و تجهیزات ماشینکاری مناسب، کاربید تنگستن میتوان آن را ماشینکاری کرد تا قطعات با کیفیت بالا با مقاومت سایشی و استحکام عالی تولید شود.