炭化タングステン 優れた硬度、耐摩耗性、強度を有することから、製造業で広く使用されている材料です。しかし、高硬度と脆さのため、この材料の加工は困難な場合があります。この記事では、様々な加工方法について説明します。 タングステンカーバイド、その考慮事項、利点、および欠点について説明します。

炭化タングステンの加工方法

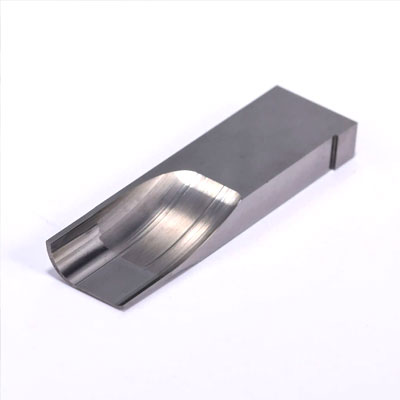

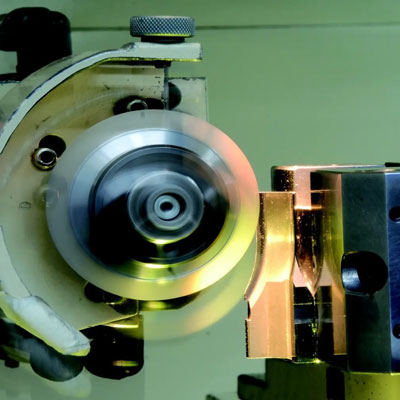

- 研削:研削は最も一般的な機械加工法である。 タングステンカーバイド研削とは、研削ホイールを用いて工作物から材料を削り取る作業です。研削ホイールは、結合剤で結合された研磨粒子でできています。研削には、ダイヤモンドまたは立方晶窒化ホウ素(CBN)の研磨粒子が一般的に使用されます。 タングステンカーバイド.

- EDM (放電加工): EDM は、電気エネルギーを使用してワークピースから材料を除去する非伝統的な加工方法です。EDM では、導電性ツールとワークピースを誘電性流体に浸します。次に、放電を使用してワークピースから材料を除去します。EDM は、複雑な形状やプロファイルによく使用されます。

- レーザー切断:レーザー切断は、高エネルギーのレーザービームを使用して切断および成形します。 タングステンカーバイドレーザービームが材料を溶かし、高圧ガスジェットが溶融材料をワークピースから吹き飛ばします。レーザー切断は薄片や複雑な形状の切断に適しています。

タングステンカーバイドの加工に関する考慮事項

- 工具の選択:工具材料の選択は機械加工にとって非常に重要です。 タングステンカーバイドダイヤモンドやCBN工具は研削によく使用されますが、 タングステンカーバイド または、EDM には銅タングステン ツールが使用されます。

- ワークピースの固定: タングステンカーバイド機械加工中に割れや欠けが生じないようにするには、ワークピースを適切に固定することが不可欠です。

- 加工パラメータ: 切削速度、送り速度、切削深さなどの加工パラメータは、工具の過度の摩耗やワークピースの損傷を避けるために慎重に選択する必要があります。

各加工方法の長所と短所

- 研削:研削は最も一般的で費用対効果の高い機械加工方法です。 タングステンカーバイド高品質の仕上がりが得られ、粗研削と仕上げ研削の両方に使用できます。ただし、研削には時間がかかり、工具寿命が限られる場合があります。

- EDM: EDMは複雑な形状やプロファイルの加工に適しています。 タングステンカーバイド熱や機械的ストレスが発生しないため、壊れやすい部品に最適です。ただし、放電加工は他の方法よりも速度が遅く、表面仕上げが粗くなる場合があります。

- レーザー切断:レーザー切断は高速かつ正確で、複雑な形状を加工することができます。 タングステンカーバイド機械的なストレスは発生せず、工具の摩耗も最小限に抑えられます。ただし、レーザー切断は高価になる場合があり、薄い部分に限られます。

結論

機械加工 タングステンカーバイド 工具の選択、ワークの固定、加工パラメータを慎重に検討する必要があります。研削は最も一般的で費用対効果の高い加工方法です。 タングステンカーバイド一方、放電加工とレーザー切断は複雑な形状や薄肉部に適しています。それぞれの方法には長所と短所があり、用途の具体的な要件に応じて適切な方法を選択する必要があります。適切な加工技術と設備があれば、 タングステンカーバイド 機械加工により、耐摩耗性と強度に優れた高品質な部品を生産できます。