Carboneto de tungstênio é um material popular utilizado na indústria por sua excelente dureza, resistência ao desgaste e resistência. No entanto, a usinagem deste material pode ser desafiadora devido à sua alta dureza e fragilidade. Neste artigo, discutiremos os vários métodos de usinagem. carboneto de tungstênio, suas considerações, vantagens e desvantagens.

Métodos de usinagem de carboneto de tungstênio

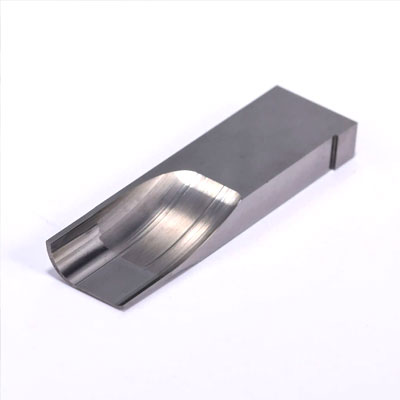

- Retificação: A retificação é o método mais comum de usinagem carboneto de tungstênio. Envolve o uso de uma roda de desbaste para remover material da peça de trabalho. A roda de desbaste é feita de partículas abrasivas unidas com um material ligante. Grãos abrasivos de diamante ou nitreto cúbico de boro (CBN) são comumente usados para desbaste. carboneto de tungstênio.

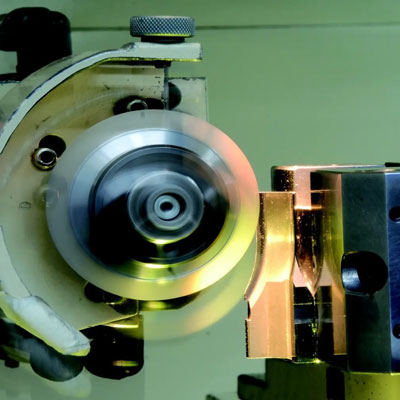

- EDM (Usinagem por Descarga Elétrica): EDM é um método não tradicional de usinagem que usa energia elétrica para remover material da peça de trabalho. Em EDM, uma ferramenta condutora e uma peça de trabalho são submersas em um fluido dielétrico. Uma descarga elétrica é então usada para remover material da peça de trabalho. EDM é frequentemente usado para formas e perfis complexos.

- Corte a laser: O corte a laser usa um feixe de laser de alta energia para cortar e moldar carboneto de tungstênioO feixe de laser derrete o material e um jato de gás de alta pressão sopra o material fundido para longe da peça de trabalho. O corte a laser é adequado para seções finas e formas complexas.

Considerações para usinagem de carboneto de tungstênio

- Seleção da ferramenta: A escolha do material da ferramenta é crucial para a usinagem carboneto de tungstênio. Ferramentas de diamante ou CBN são comumente usadas para retificação, enquanto carboneto de tungstênio ou ferramentas de cobre-tungstênio são usadas para EDM.

- Fixação da peça de trabalho: Devido à fragilidade da carboneto de tungstênio, a fixação adequada da peça de trabalho é essencial para evitar rachaduras ou lascas durante a usinagem.

- Parâmetros de usinagem: Parâmetros de usinagem como velocidade de corte, taxa de avanço e profundidade de corte devem ser cuidadosamente selecionados para evitar desgaste excessivo da ferramenta ou danos à peça de trabalho.

Vantagens e desvantagens de cada método de usinagem

- Retificação: A retificação é o método de usinagem mais comum e econômico carboneto de tungstênio. Proporciona um acabamento de alta qualidade e pode ser usado tanto para desbaste quanto para acabamento. No entanto, o desbaste pode ser demorado e a vida útil da ferramenta pode ser limitada.

- EDM: A EDM é adequada para usinagem de formas e perfis complexos em carboneto de tungstênio. Não produz calor ou estresse mecânico, tornando-o ideal para peças frágeis. No entanto, a eletroerosão pode ser mais lenta do que outros métodos e produzir um acabamento superficial mais áspero.

- Corte a laser: O corte a laser é rápido e preciso e pode produzir formas complexas em carboneto de tungstênio. Não produz estresse mecânico e o desgaste da ferramenta é mínimo. No entanto, o corte a laser pode ser caro e se limita a seções finas.

Conclusão

Usinagem carboneto de tungstênio requer consideração cuidadosa da seleção de ferramentas, fixação da peça e parâmetros de usinagem. A retificação é o método de usinagem mais comum e econômico. carboneto de tungstênio, enquanto a eletroerosão e o corte a laser são adequados para formas complexas e seções finas. Cada método tem suas vantagens e desvantagens, e a escolha do método dependerá dos requisitos específicos da aplicação. Com as técnicas e equipamentos de usinagem adequados, carboneto de tungstênio pode ser usinado para produzir peças de alta qualidade com excelente resistência ao desgaste e resistência.