Wolframcarbid ist ein beliebtes Material in der Fertigung aufgrund seiner hervorragenden Härte, Verschleißfestigkeit und Festigkeit. Die Bearbeitung dieses Materials kann jedoch aufgrund seiner hohen Härte und Sprödigkeit eine Herausforderung darstellen. In diesem Artikel werden wir die verschiedenen Bearbeitungsmethoden erläutern. Wolframcarbid, ihre Überlegungen, Vorteile und Nachteile.

Methoden zur Bearbeitung von Wolframcarbid

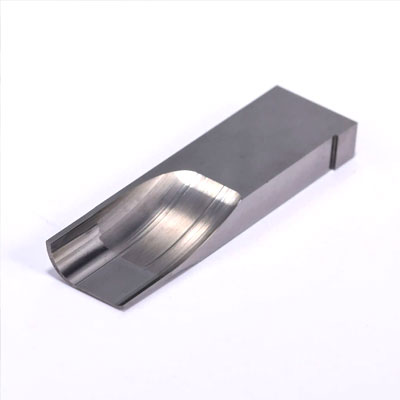

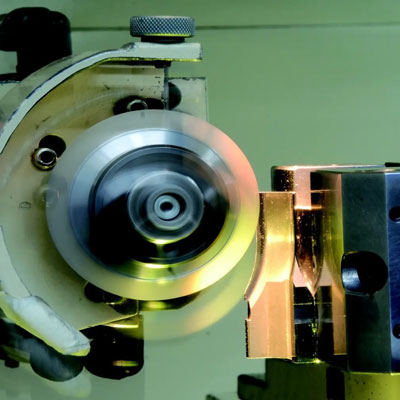

- Schleifen: Schleifen ist die häufigste Methode der Bearbeitung WolframcarbidDabei wird eine Schleifscheibe verwendet, um Material vom Werkstück abzutragen. Die Schleifscheibe besteht aus Schleifpartikeln, die durch ein Bindemittel miteinander verbunden sind. Diamant- oder kubisches Bornitrid (CBN)-Schleifkörner werden üblicherweise zum Schleifen verwendet. Wolframcarbid.

- EDM (Electrical Discharge Machining): EDM ist eine nicht-traditionelle Bearbeitungsmethode, bei der elektrische Energie verwendet wird, um Material vom Werkstück zu entfernen. Beim Erodieren werden ein leitfähiges Werkzeug und ein Werkstück in eine dielektrische Flüssigkeit getaucht. Anschließend wird mittels elektrischer Entladung Material vom Werkstück entfernt. EDM wird häufig für komplexe Formen und Profile eingesetzt.

- Laserschneiden: Beim Laserschneiden wird ein hochenergetischer Laserstrahl zum Schneiden und Formen verwendet WolframcarbidDer Laserstrahl schmilzt das Material, und ein Hochdruckgasstrahl bläst das geschmolzene Material vom Werkstück weg. Laserschneiden eignet sich für dünne Abschnitte und komplizierte Formen.

Überlegungen zur Bearbeitung von Wolframkarbid

- Werkzeugauswahl: Die Wahl des Werkzeugmaterials ist entscheidend für die Bearbeitung Wolframcarbid. Zum Schleifen werden üblicherweise Diamant- oder CBN-Werkzeuge verwendet, während Wolframcarbid oder Kupfer-Wolfram-Werkzeuge werden für die Funkenerosion verwendet.

- Werkstückbefestigung: Aufgrund der Sprödigkeit von Wolframcarbid, ist eine ordnungsgemäße Werkstückbefestigung unerlässlich, um Risse oder Absplitterungen während der Bearbeitung zu vermeiden.

- Bearbeitungsparameter: Bearbeitungsparameter wie Schnittgeschwindigkeit, Vorschubgeschwindigkeit und Schnitttiefe sollten sorgfältig ausgewählt werden, um übermäßigen Werkzeugverschleiß oder Schäden am Werkstück zu vermeiden.

Vor- und Nachteile jeder Bearbeitungsmethode

- Schleifen: Schleifen ist die häufigste und kostengünstigste Methode der Bearbeitung WolframcarbidEs sorgt für ein hochwertiges Finish und kann sowohl zum Grob- als auch zum Feinschleifen verwendet werden. Das Schleifen kann jedoch zeitaufwändig sein und die Standzeit des Werkzeugs kann begrenzt sein.

- EDM: EDM eignet sich zum Bearbeiten komplexer Formen und Profile in WolframcarbidEs erzeugt weder Hitze noch mechanische Spannung und ist daher ideal für zerbrechliche Teile. EDM kann jedoch langsamer als andere Methoden sein und eine rauere Oberflächenbeschaffenheit erzeugen.

- Laserschneiden: Laserschneiden ist schnell und präzise und kann komplizierte Formen erzeugen in Wolframcarbid. Es entsteht keine mechanische Belastung und der Werkzeugverschleiß ist minimal. Das Laserschneiden kann jedoch teuer sein und ist auf dünne Abschnitte beschränkt.

Abschluss

Bearbeitung Wolframcarbid erfordert eine sorgfältige Auswahl der Werkzeuge, der Werkstückbefestigung und der Bearbeitungsparameter. Schleifen ist die häufigste und kostengünstigste Methode der Bearbeitung Wolframcarbid, während EDM und Laserschneiden für komplexe Formen und dünne Abschnitte geeignet sind. Jede Methode hat ihre Vor- und Nachteile, und die Wahl der Methode hängt von den spezifischen Anforderungen der Anwendung ab. Mit den richtigen Bearbeitungstechniken und -geräten Wolframcarbid kann bearbeitet werden, um hochwertige Teile mit hervorragender Verschleißfestigkeit und Festigkeit herzustellen.