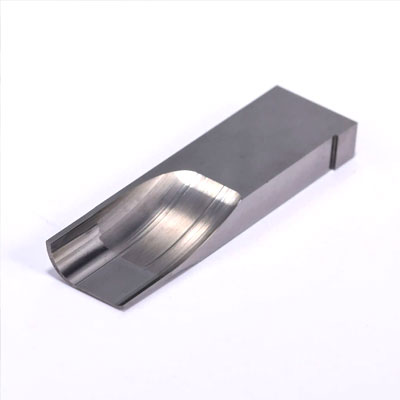

Węglik wolframu jest popularnym materiałem stosowanym w produkcji ze względu na doskonałą twardość, odporność na zużycie i wytrzymałość. Jednak obróbka tego materiału może być trudna ze względu na jego wysoką twardość i kruchość. W tym artykule omówimy różne metody obróbki węglik wolframu, ich rozważania, zalety i wady.

Metody obróbki węglika wolframu

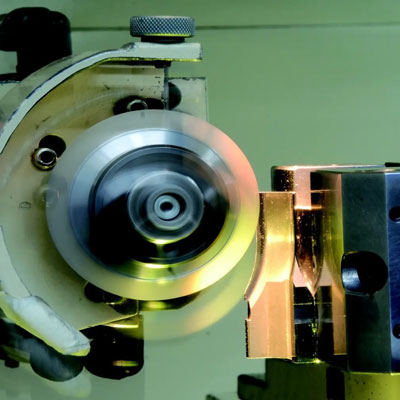

- Szlifowanie: Szlifowanie jest najpowszechniejszą metodą obróbki węglik wolframu. Polega na użyciu tarczy szlifierskiej do usuwania materiału z przedmiotu obrabianego. Tarcza szlifierska składa się z cząstek ściernych połączonych ze sobą materiałem wiążącym. Do szlifowania powszechnie stosuje się diamentowe lub sześcienne ziarna ścierne azotku boru (CBN) węglik wolframu.

- EDM (Electrical Discharge Machining): EDM to niestandardowa metoda obróbki, która wykorzystuje energię elektryczną do usuwania materiału z przedmiotu obrabianego. W EDM przewodzące narzędzie i przedmiot obrabiany są zanurzane w dielektrycznym płynie. Następnie do usuwania materiału z przedmiotu obrabianego stosuje się wyładowanie elektryczne. EDM jest często stosowane w przypadku skomplikowanych kształtów i profili.

- Cięcie laserowe: Cięcie laserowe polega na użyciu wysokoenergetycznej wiązki laserowej do cięcia i kształtowania węglik wolframu. Promień lasera topi materiał, a strumień gazu pod wysokim ciśnieniem wydmuchuje stopiony materiał z obrabianego przedmiotu. Cięcie laserowe nadaje się do cienkich przekrojów i skomplikowanych kształtów.

Rozważania dotyczące obróbki węglika wolframu

- Wybór narzędzia: Wybór materiału narzędzia ma kluczowe znaczenie dla obróbki węglik wolframuDo szlifowania powszechnie stosuje się narzędzia diamentowe lub CBN, podczas gdy węglik wolframu lub do obróbki elektroerozyjnej stosuje się narzędzia miedziano-wolframowe.

- Mocowanie przedmiotu obrabianego: Ze względu na kruchość węglik wolframuWłaściwe mocowanie przedmiotu obrabianego jest niezbędne, aby zapobiec pęknięciom i odpryskom podczas obróbki.

- Parametry obróbki: Parametry obróbki, takie jak prędkość skrawania, posuw i głębokość skrawania, należy dobrać ostrożnie, aby uniknąć nadmiernego zużycia narzędzia lub uszkodzenia przedmiotu obrabianego.

Zalety i wady każdej metody obróbki

- Szlifowanie: Szlifowanie jest najpowszechniejszą i najbardziej ekonomiczną metodą obróbki węglik wolframu. Zapewnia wysokiej jakości wykończenie i może być stosowany zarówno do szlifowania zgrubnego, jak i wykańczającego. Jednak szlifowanie może być czasochłonne, a żywotność narzędzia może być ograniczona.

- EDM: EDM nadaje się do obróbki skomplikowanych kształtów i profili węglik wolframu. Nie wytwarza ciepła ani naprężeń mechanicznych, co czyni go idealnym do delikatnych części. Jednak EDM może być wolniejsze niż inne metody i może powodować szorstkość powierzchni.

- Cięcie laserowe: Cięcie laserowe jest szybkie i precyzyjne, a także umożliwia produkcję skomplikowanych kształtów. węglik wolframu. Nie powoduje naprężeń mechanicznych, a zużycie narzędzi jest minimalne. Jednak cięcie laserowe może być drogie i jest ograniczone do cienkich sekcji.

Wniosek

Obróbka skrawaniem węglik wolframu wymaga starannego rozważenia wyboru narzędzia, mocowania przedmiotu obrabianego i parametrów obróbki. Szlifowanie jest najpowszechniejszą i najbardziej opłacalną metodą obróbki węglik wolframu, podczas gdy EDM i cięcie laserowe nadają się do skomplikowanych kształtów i cienkich przekrojów. Każda metoda ma swoje zalety i wady, a wybór metody będzie zależał od konkretnych wymagań zastosowania. Przy odpowiednich technikach obróbki i sprzęcie, węglik wolframu można obrabiać mechanicznie, uzyskując wysokiej jakości części o doskonałej odporności na zużycie i wytrzymałości.